The problem with old school.

As we all know, in manufacturing - time is definitely money. Finding a way to speed up production, reduce waste and machine time as well as operator costs is top of most, if not all fabricators wish lists. Today we are going to discuss a crucial part of the fabrication mix - bending simulation software.

In the not so distant past (and in fact, the present), prototyping involved taking a few cut parts to the press brake whereupon the operator would select tooling he thought would do the job. The operator would proceed to bend the part, working out a bend sequence along the way. After some time, several tool changes and probably a few scrapped parts later, the realisation that the part cannot be bent correctly is arrived at.

This process is costly and frustrating as it ties up your press brake, and a skilled operator not to mention other machines like laser cutters, plasma cutters and guillotines, when these machines should be meeting production targets and deadlines.

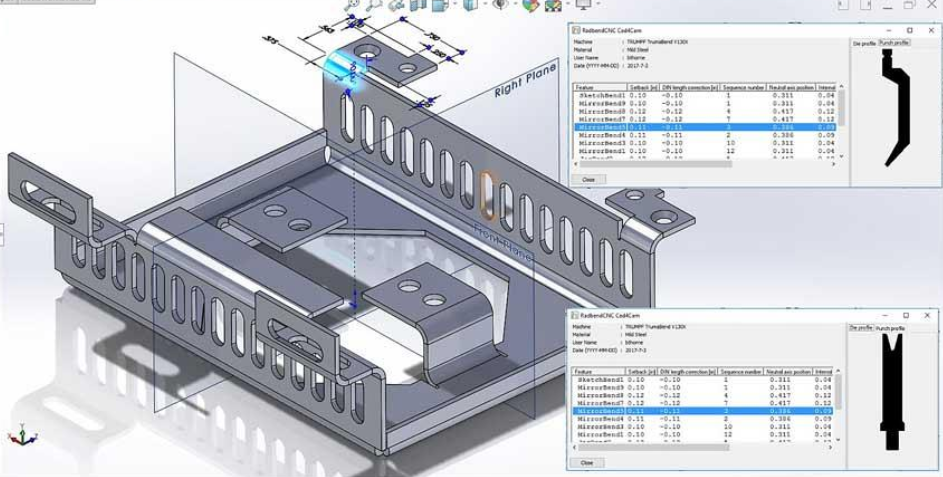

Drafting software such as SolidWorks can integrate seamlessly with various brands of bend simulation software.

The solution is new school.

The solution then would be to move the process up-stream in the production cycle. By this we mean that the problem of prototyping on a machine, becomes a simulated process using software to quickly and efficiently determine tool selection, bend sequencing, collision detection and importantly, safety considerations. This step in the production cycle is done immediately after the part has been drawn up, and is in actual fact complementary to the drafting process. When a drawing is converted to a virtual part, and interrogated by the simulation software, feed- back can be given to the drafting department and any adjustments made to help with a successful outcome within the constraints of existing tooling or machine types that are on the floor.

If we were to delve a little deeper in to the capabilities of a typical offline bending simulation software package we would find several key areas that work together to all but eliminate the need for physical prototyping.

Imported flat drawing before conversion.

Part conversion - from flat drawing to three dimensional part

When a drawing is imported in a format such as .dxf, the bending software is able to take data embedded as layers in the drawing and use it to create a three dimensional part. This step is key to helping operators to visualise the part structure and also to understand bend sequences.

Flat drawing converted to 3D part.

The bend simulation software interrogates the flat drawing and using data embedded in the layers of the drawing determines amongst other things bend angle, upward or downward bends, material thickness, type of material, external and internal radii, external and internal allowances, and more. Once in 3D the part can be manipulated and if any changes are made, flattened again to determine unfolded length and width calculations and then sent back to the design department in a feed back loop to arrive at a feasable part.

Tool library with top and bottom tool systems.

Machine and tool library

Once the bending software has been correctly set up with the press brakes available and the various tools at your disposal, you are able to select the press brake on which you intend to bend the part. The software will instantly evaluate whether the part can be made and provide feedback immediately to the designers and operators.

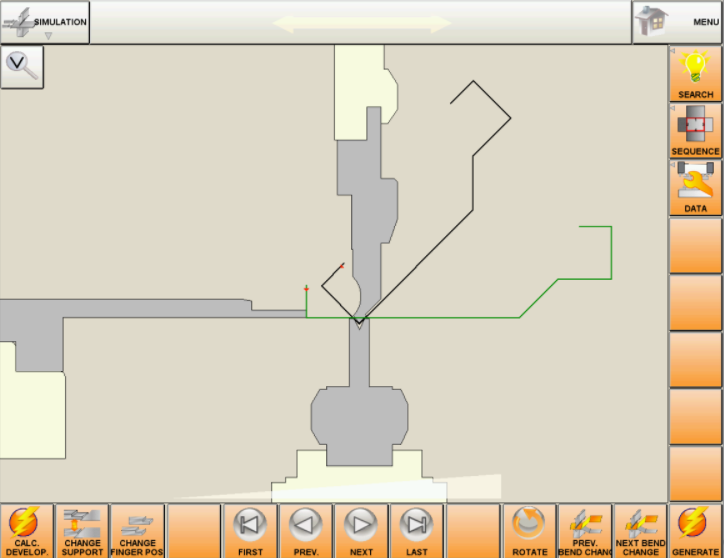

Determining optimum bend sequence and collision detection.

Bend simulation and sequencing

Offline bending software can carry out bend simulations using any machine and tooling combination that makes the bending of the part possible, from the library. During this process you can use the feedback to determine the bend sequence and override it if necessary, optimise tool selection or adjust budgets and lead times to allow for tool purchasing. Collision detection also takes place, and you can make adjustments accordingly to the bend sequence or how the back gauges are used, to resolve it.

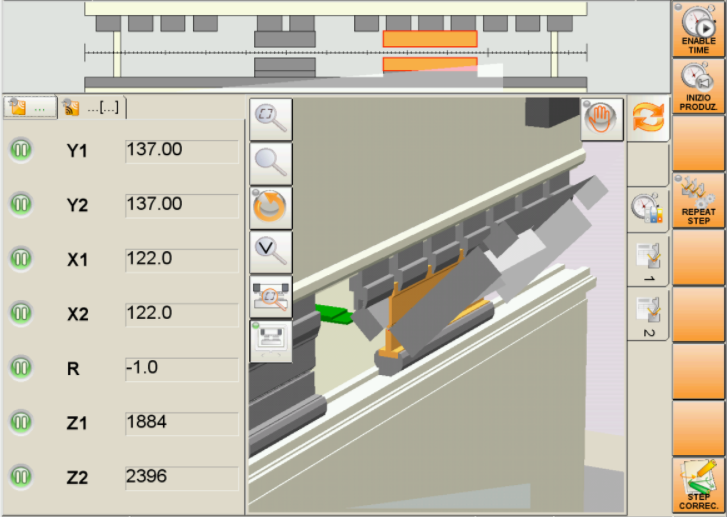

Exporting a machine compatible bend programme with all the meta data required

Once the part has been finalised in the offline bending software, it can be exported to a format compatible with the press brake’s control. The file will contain other data that makes it incredibly useful - bend sequence, tool selection, material type, crowning, back gauge positions and much more is embedded in the file essentially meaning the machine (once correctly tooled up) is ready to bend immediately. This is not possible with a flat .dxf file import.

Other hidden but very positive benefits:

Evaluating the impact a new set of tooling will have on shop wide production

Imagine for a moment you are considering purchasing custom tooling for a job. You may have done your homework in determining it is right for producing that part, but why not use the bending software to further extract value from the purchase? It could quickly and easily tell you whether other parts in your library could benefit from the new tools, perhaps performing more bends without tool changes, or shortening a sequence.

Institutional memory

All too often we find ourselves with the problem of a key member of staff leaving the business for one reason or another. This presents a very real and damaging risk to the company as institutional memory leaves the building. The best operators will take with them the experience they have of your fabrication works and the best ways to deliver parts with your tools and machines. However, this can be mitigated to a large extent with bending software, since this expertise can be documented and recorded, and constantly improved - meaning you always retain the best way to carry out your production.

Operator guidance during bend simulation shows axes data, bend station and orientation of part.

The best way to the do the job

Training press brake operators to in the art of tool selection, bend sequencing and press brake operation can be a huge challenge. Further, when more than one operator is used for shift work or cover, repeatability and consistent quality is a challenge to maintain. By using bending software to generate a standardised part programme, each operator will not only learn by doing, they will also form the same part, in the same way, ensuring consistent, quality results. In the past operators would have used their (varying) quality of judgement to produce a part. Now there is only the one way, which is the best way.

Conclusion

If a press brake is not bending, it follows that it is not making money. Consider if it is bending, but producing parts that are incorrect and inconsistent. Now your press brake is actually losing you money. In addition, if your operators leave the business and new staff members are taken on, the loss of that valuable expertise and lack of documented methodologies for bending means now the HR function of your business is also costing you money.

For many businesses buying their first press brake, offline software may seem like a luxury, especially as it often carries a premium price tag. Our argument is that is is absolutely worth the money and if bought at the outset, will set a solid foundation for growth of the business and it’s production. Existing fabrication shop owners with press brakes will almost immediately realise an improvement in output, consistency and safety.

We hope you have enjoyed the fourth part of our series of things to consider when buying a press brake. Why not join us again next time when we have a look at the 5th consideration - maintenance and servicing.