Yawei HPI CNC Turret Punch

Yawei HPI CNC Turret Punch

All Yawei steel machining processes (frames, beams, tables, etc) are built within a temperature controlled & dust-free facility, ensuring that exact machining specifications are achieved:

Siemens™ (Germany) 840-D CNC control system

Adopts German H+L hydraulic system

Punch stroke rates up to 1000 hits /min

Excellent cost-performance ratio

Patented Nisshinbo technology keeps touch auto-index design, with high precision and accuracy

FULL SPECIFICATION LISTED BELOW

HPI Series Tooling Configurations:

26 TOOL STATIONS

38 TOOL STATIONS

standard

40 TOOL STATIONS

HPI Series Features:

- SERVO RAM DESIGN

- ENERGY EFFICIENCY

- HIGH SPEED, LOW NOISE

- TURRET STRUCTURE

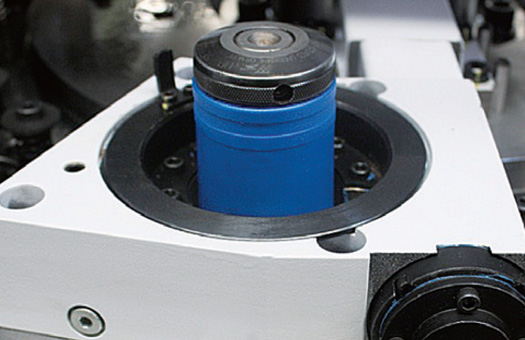

- TOOLING AUTO-INDEX

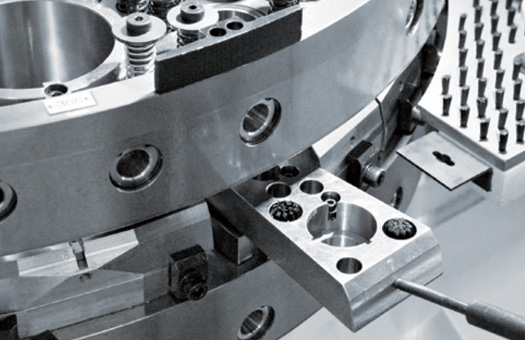

- LOWER DIE HOLDER – FAST CHANGING

- 17" SIEMENS TOUCH SCREEN

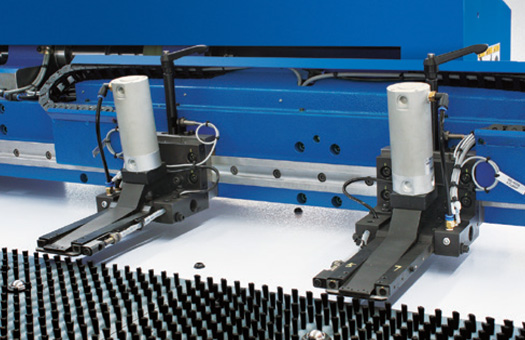

- FEEDING STRUCTURE

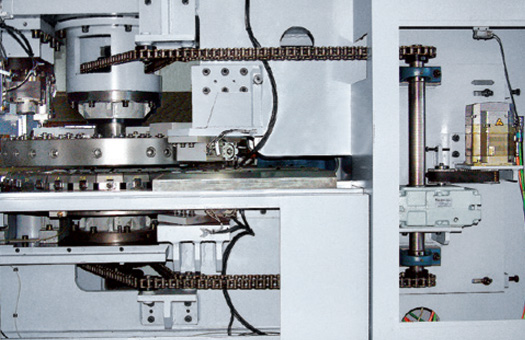

- TURRET DRIVE

Yawei's ram design uses a single servo motor coupled directly to the crankshaft for the highest possible punching performance and reliability.

This simplified design enhances component life and ensures positioning accuracy by a closed loop servo control system.

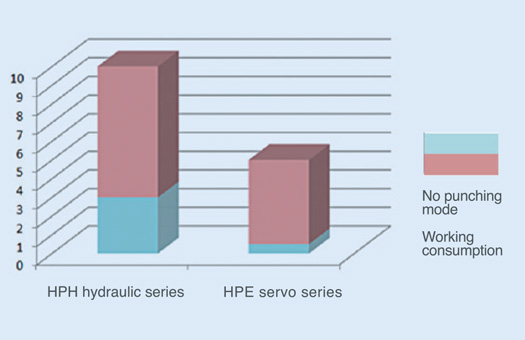

High energy efficiency by calculating and controlling the punching force. Additionally, the energy generated from each break can be recycled for a second acceleration.

This movement halves the hydraulic consumption. Complete servo control without hydraulic oil helps decrease maintenance costs.

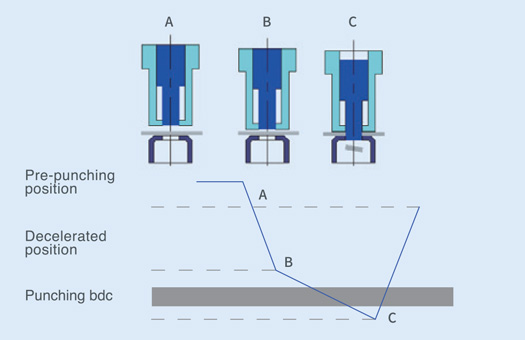

Advanced punching technology provides full control of the ram speeds, stroke and forming combined with low noise and energy consumption.

High precision seamless mechanical structure, no internal abnormal noise during high-speed movements.

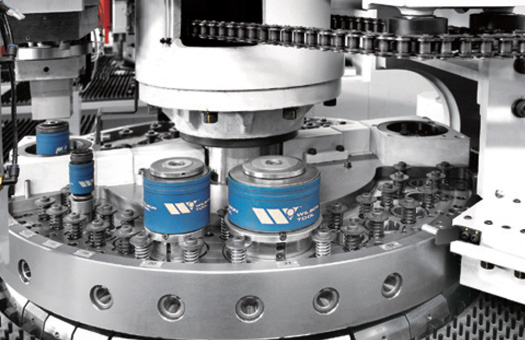

Turret processed through one-time clamping precision machining with high strength alloy casting steel, strong antioxidant and carrying capacity, excellent vibration control and precision-oriented performance.

Plate deformation becomes a thing of the past when punching high-density holes.

Nisshinbo patented keeping-touch Auto-Index design eliminates secondary positioning errors.

Our repositioning accuracy is within 0.03mm by linkage transmission control of the T axis, worm gear and rod.

Special die removal device shortens the changing time. This means your working efficiency rises, with precise positioning devices this guarantees the accuracy of any repositioning.

With 17 inch touch human-machine interface, in view of the punch design, simple operation, powerful functions. Integrated graphics, offline simulation, dynamic simulation, mold contrast special functions such as punch.

Big lead high precision grinding ball screw, control without using segmented compensation, the sports location accuracy is higher, running noise smaller, ball screw comprehensive live longer.

Standard pneumatic swing high strength clamp, mature and stable structure, adaptive plate.

Compact structure, reasonable load power matching, high stability, can according to the system instruction, fast response on the power, precision calibration turret orientation device can ensure accurate choice knife.

HPI Series Specifications:

| PARAMETERS | UNIT | HPE-3044 | HPE-3047 | HPE-3048 | HPE-3057 | HPE-3058 | HPE-3078 |

|---|---|---|---|---|---|---|---|

| Max. Processing sheet thickness | mm | MS = 6.35 SS = 4.00 |

MS = 6.35 SS = 4.00 |

MS = 6.35 SS = 4.00 |

MS = 6.35 SS = 4.00 |

MS = 6.35 SS = 4.00 |

MS = 6.35 SS = 4.00 |

| Max. Processing sheet size | mm | 1250 x 2500 | 1250 x 4000 | 1250 x 5000 | 1500 x 4000 | 1500 x 5000 | 2000 x 5000 |

| Max. Punch diameter | mm | ø88.9 | ø88.9 | ø88.9 | ø88.9 | ø88.9 | ø88.9 |

| Max. Speed of plate movement | m/min | 102 | 102 | 102 | 102 | 102 | 102 |

| Turret speed | rpm | 30 | 30 | 30 | 30 | 30 | 30 |

| Punch accuracy | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 |

| Ram stroke rates | cpm | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

| CNC Axes | 5 | (X,Y,T,C,Z) | (X,Y,T,C,Z) | (X,Y,T,C,Z) | (X,Y,T,C,Z) | (X,Y,T,C,Z) | (X,Y,T,C,Z) |

| Total power consumption | kW | 6.1 | 6.1 | 6.1 | 6.1 | 6.1 | 6.1 |

| Overall dimensions (LxWxH) | mm | 5410 x 2300 x 2260 | 5410 x 4000 x 2260 | 5410 x 5000 x 2260 | 5910 x 4000 x 2260 | 5910 x 5000 x 2260 | 6910 x 5000 x 2450 |

| Machine weight | Kg | 14,000 | 15,000 | 16,000 | 18,000 | 19,000 | 25,500 |