A brief introduction to one of the most versatile machine tools available for the money.

Those who hear the phrase ‘I love my iron worker’ fall into two camps - they either smile and nod in agreement or they ask ‘What is an ironworker?’ and get the answer ‘you don’t know what you are missing!’. The iron worker, also known as ‘punch shear cropper’, or simply ‘cropper’ (which is a disservice to this incredible machine) was first designed and built as early as the 1960’s and immediately made an impact on the fabrication industry. The machines were powerful, compact and versatile - performing many different functions in the fab shop quickly and efficiently and at a relatively low cost to performance ratio. An iron worker could punch, shear, crop, notch, bend and more making it a fabricators best friend and establishing itself as a key component of the production mix.

How does it work?

An iron worker uses either mechanical or hydraulic power to provide the force to its tool systems. The mechanical machines are much bigger and noisier than hydraulic machines, as they make use of a flywheel to bring the ram down in a single cycle both downward and upward, with no means of stopping until the cycle is complete. Hydraulic ironworkers make use of electronics that manage the valves controlling oil to the hydraulic pistons, allowing much more granular and safe control to the machines movement. These machines can be inched down and up at different speeds, or made to perform an entire cycle and even automated completely with PLC systems for high production requirements.

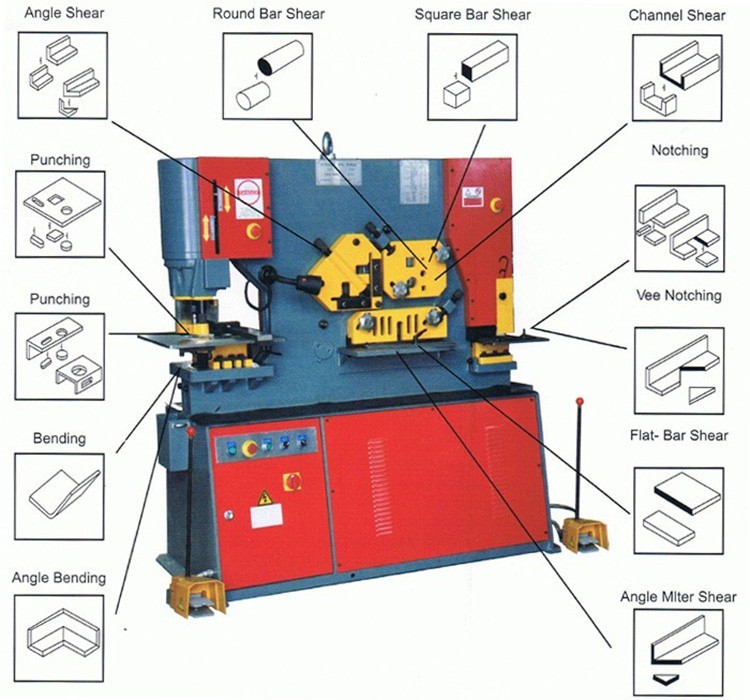

The most popular iron worker design consists of a central ram that is housed inside the ironworkers body and pivots on an off centre point, to provide the shearing, punching or notching force to blades and tooling at various stations located on the body of the machine as per the illustration alongside. A variation of this is to have a single hydraulic cylinder power this ram, whilst another powers the punching station. These two cylinders operate independently of each other, effectively allowing for ‘dual station’ working and higher productivity. In the case of a mechanical machine, there is no option for dual station working, as the power is derived from a single flywheel source.

Powwwwwwer!

One thing is for sure - most people underestimate the sheer power of these machines. An iron worker’s general capacity is expressed in tons, for example 60 tons, or 90 tons and up to 200 tons. This translates to the machine’s ability to punch a certain diameter in a certain thickness of mild steel, or to shear a certain thickness of round bar, or plate. For example - a relatively small capacity ironworker such as a 60 tonner, can punch a 25mm hole in 16mm material, whilst it can cut 120mm x 12mm equal angle iron! As the machine capacity increases these numbers get even more amazing. A 200 ton iron worker can punch 40mm diameter holes in 40mm plate and cut 200mm x 12mm equal angle iron.

As you can see, very efficient and direct delivery of power is achieved with an iron worker, allowing significant performance for a relatively low cost.

So what can you do with an iron worker?

The options open to fabricators once they purchased a well specced iron worker are many. A typical hydraulic ironworker will offer you the ability to punch flat plate or bar, angle iron, I beam, channel and other configurations of structural steel. It will allow you shear these items at 90 degrees or 45 degrees as well as offer standard flat plate shearing. You can also cut square bar, and round bar of varying thicknesses. The notching station allows for just that, notching of material for box bending, frame making or any other application. Finally, pipe notching, V notching, tubing shearing, specialty punching and bending are all possible on an iron worker with the correct tooling.

Many hydraulic iron workers will also come with some very handy options included, such as optional press brake tooling. This is very useful for thick material bending over short lengths, and prevents inappropriate bending on your press brake that may damage your valuable lengths of tooling or even the press brake itself. Other features like a cut to length back stop allow the cropping or cutting functions of the machine to be semi-automated, utilising a touch plate in the back stop to trigger the cutting function when the material makes contact with the back stop.

Add to this the fact that two operators can work independently of each other (provided it is a dual hydraulic cylinder machine) and you have a high utility machine with great production potential.

All hail the Iron worker!

As you can see, we are also fans of this machine and who wouldn’t be. When we are asked to describe the machine and provide a demo to a client who has never used one, the response is almost always the same - ‘Wow, I didn’t know it was so useful’.

Give yourself two minutes to think about where and how an iron worker will fit into your fabrication works and then give us a call for a chat. We are very sure it will find a good home and prove its return on investment in no time!